Pneumatic 22 Gauge 3/8 in Crown Upholstery Stapler 7116/436

Pneumatic 22 Gauge 3/8 in Crown Upholstery Stapler 7116/436Pneumatic 22 Gauge 3/8 in Crown Upholstery Stapler 7116/436,This fine wire staple gun is ideal for upholstery, automotive vinyl and other fabric projects.The stapler uses 22 Gauge, 3/8 in. crown staples and drives 1/4 in. through 5/8 in. length. ● Perfect stapler for auto and marine vinyl trim, upholstery, small furniture repairs, picture frames and many more useful applications. ● Tool-free depth adjusts. ● 360° adjustable exhaust. ● non-marring tip and comfortable grip allow for a user-friendly experience. ● Long nose design for tight space. |

| Model: | Pneumatic 22 Gauge 3/8 in Crown Upholstery Stapler 7116/436 |

| Air Tool Type: | Air Stapler |

| Tool Diamensions: | 190mm x 45mm x 220mm |

| Net Tool Weight: | 1.10kgs (2.42 lbs) |

| Operate Pressure: | 60-100psi (4-7bar) |

| Load Capacity: | 190 staples |

| Staples Type: | 22 Guage 71 Series Fine Wire Staples |

| Staples Crown: | 3/8″(9.0mm) |

| Staples Shank Diameter: | 0.030″(0.75mm) x 0.024″(0.60mm) |

| Staples Length: | 1/6″(4mm)~5/8″(16mm) |

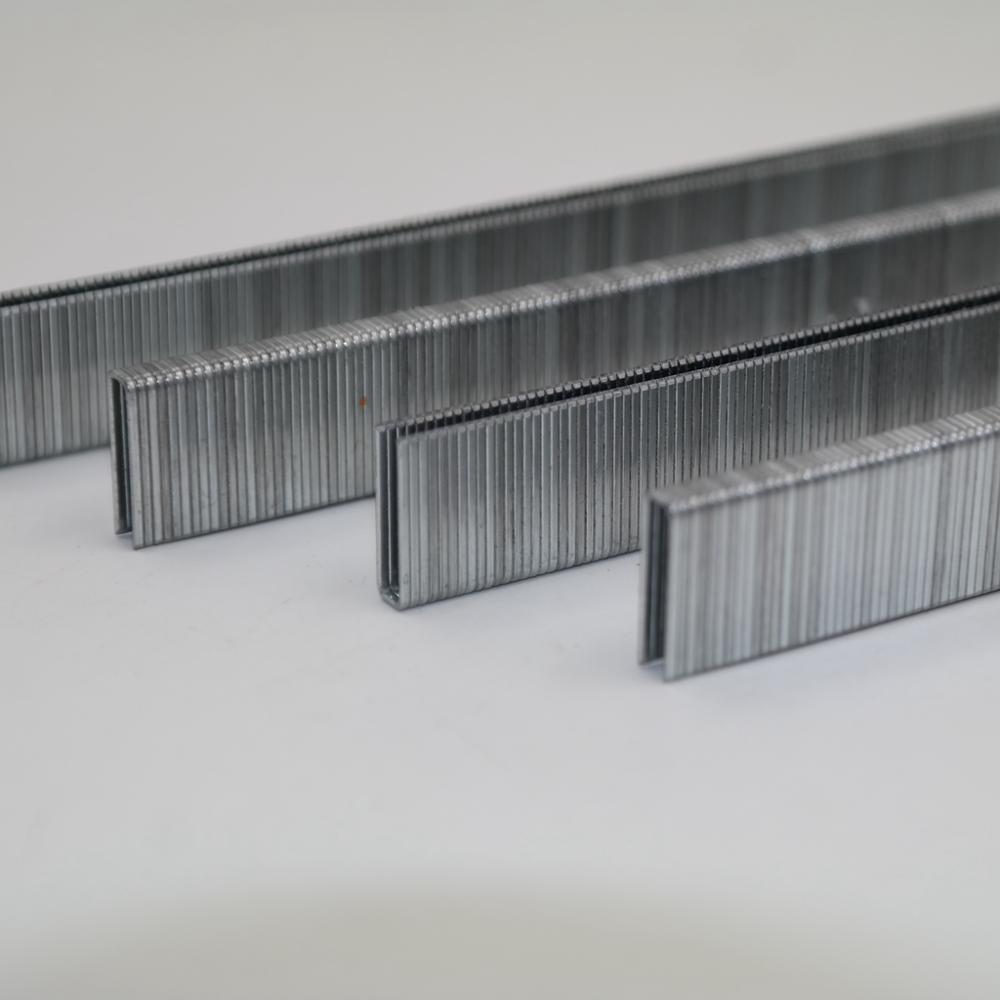

| 22 Guage 71 Series Fine Wire Staples |

| Staples Crown:3/8″(9.0mm) |

| Staples Shank Diameter:0.030″(0.75mm) x 0.024″(0.60mm) |

| Staples Length:1/6″(4mm)~5/8″(16mm) |

Lightweight body for easy operation.

Lightweight body for easy operation.

Low noisy have good feedback from suctoerm.

Low noisy have good feedback from suctoerm.

Powerful strength and excellent durability.

Powerful strength and excellent durability.

Long nose design for tight space.

Long nose design for tight space.

Same as 71/16-436

Same as 71/16-436

Furniture manke and repair.

Cloth and wood connection.

Picture frams.

Decoration.

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don’t work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don’t work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston o-rings | |||

| 2 | Failed to get driver(piston unit) back to the correct position completely. | 1.The driver(piston unit) is not straight or the driver guide(nose) is wrong assembled. | Straighten the driver(piston unit) or verify driver guide(nose) and magazine | |

| 2.Worn or damaged nozzle | Check and replace nozzle | |||

| 3.The space between piston o-ring and cylinder is too tight. | Check if the cylinder is adequate lubrication or replace the o-ring on the piston. | |||

| 3 | Work weakly and sluggishly | 1. Worn or damaged piston o-ring | Check and replace piston o-ring | |

| 2.Inadequate lubrication for head valve piston o-rings or too tight head valve piston o-rings | Place 2 or 6 drops of oil on o-rings or replace head valve piston o-rings | |||

| 3.Dirt in the nozzle | Check and clean the nozzle | |||

| 4 | Tool jams frequently | 1.Damaged or Worn driver (piston unit) | Check and replace driver (piston unit) | |

| 2.Damaged or Worn driver guide (nose) | Check and replace driver guide (nose) | |||

| 3.Driver guide cover is bent,so the space between driver guide cover and driver guide is too big | Check and replace driver guide cover | |||

| 5 | Nail can not be shot | 1. Driver (piston unit) can’t return to the correct position. | Refer to no. 1 Symptom | |

| 2.Driver guide(nose) can not match magazine well | Check and correct the position between driver guide(nose) and magazine | |||

| 3.Worn or damaged nail pusher compression spring | Check and replace nail pusher compression spring | |||